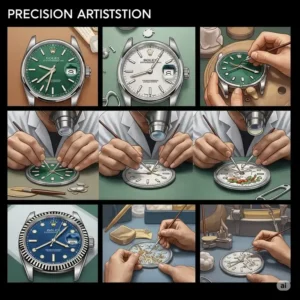

When it comes to luxury timepieces, few elements command as much attention and admiration as the rolex watch dial. This intricate component serves as the face of your investment, dictating not only functionality but also the overall aesthetic appeal that has made Rolex synonymous with precision and prestige. Whether you’re considering a rolex dial replacement, exploring rolex watch dial variations for customization, or seeking to understand the technical intricacies behind these masterpieces, this comprehensive guide delivers expert insights that matter to collectors, enthusiasts, and professional watchmakers alike.

✨Was this helpful? Spread the word! 🚀

Quick Comparison: Rolex Watch Dial Options

| Dial Type | Material | Compatibility | Price Range | Best For |

|---|---|---|---|---|

| Factory OEM | Various metals | Original models | $300-$2,000+ | Restoration |

| Aftermarket Custom | Mother of pearl, diamonds | Multiple models | $150-$800 | Personalization |

| Vintage Original | Age-specific materials | Classic models | $500-$3,000+ | Collectors |

| Diamond-Set | Factory diamonds | Select models | $1,000-$5,000+ | Luxury upgrade |

| Mother of Pearl | Natural MOP | Various sizes | $200-$1,200 | Elegant appeal |

| Roman Numeral | Metal/enamel | Traditional models | $250-$900 | Classic styling |

| Arabic Numeral | Various finishes | Sport models | $180-$700 | Modern look |

Top 7 Rolex Watch Dial Options: Expert Analysis

1. Ewatchparts 3 SET Watch Hand Compatible with Rolex 2130/2135 ⭐

This professional-grade aftermarket set includes three complete sets of luminous watch hands specifically engineered for lady Rolex quickset movements #2130-2135. Compatible with case numbers 67000, 67180, 67480, and 69160, these gold-colored hands feature diamond dial compatibility and Swiss-made precision.

Key Specifications:

- ✅ Movement compatibility: 2130/2135

- ✅ Case compatibility: Multiple models

- ✅ Material: Gold-colored luminous

- ✅ Quantity: 3 sets (9 pieces total)

- ✅ Quality guarantee: 100% satisfaction

2. ZXZZNO Metal Watch Band for Rolex Dial Compatibility 🔧

Designed for rolex watch dial sizes ranging from 36mm to 41mm, this premium stainless steel bracelet accommodates Submariner, GMT Master II, Daytona, Datejust, and Day-Date models. The 914L stainless steel construction ensures durability that matches original Rolex specifications.

Technical Features:

- ✅ Dial compatibility: 36mm, 40mm, 41mm

- ✅ Material: 914L stainless steel

- ✅ Models: Submariner, GMT, Daytona, Datejust

- ✅ Includes: Installation tools and springs

- ✅ Finish: Brushed solid construction

3. Ewatchparts Sapphire Crystal Compatible with Rolex Day-Date II 💎

This aftermarket sapphire crystal features precise 41mm sizing for Day-Date II model 218235, incorporating 2.5x cyclops magnification and pressure-resistant nylon gasket for waterproof integrity.

Crystal Specifications:

- ✅ Size: 41mm diameter

- ✅ Magnification: 2.5x cyclops

- ✅ Material: White sapphire

- ✅ Gasket: Pressure-resistant nylon

- ✅ Clarity: No lens effect distortion

4. Rolex Watch Repair Tool – 5537 Back Case Opener Kit 🛠️

Essential for accessing rolex watch dial components, this professional-grade opener includes six graduated dies (18.50mm to 29.50mm) constructed from high-quality alloy steel for precision work on Oyster-style cases.

Tool Kit Contents:

- ✅ Six graduated dies: 18.50-29.50mm

- ✅ Material: Alloy steel construction

- ✅ Compatibility: Rolex Oyster models

- ✅ Storage: Organized carrying case

- ✅ Professional grade: Swiss-made quality

5. Ewatchparts Watch Hand Compatible with Rolex Movement 2230/2235 ⚡

Specifically designed for rolex dial configurations featuring diamond settings, these gold-finished hands accommodate movements 2230/2235 and case numbers 76188, 76198, and 76243.

Hand Specifications:

- ✅ Movement: 2230/2235 compatibility

- ✅ Finish: Gold with diamond dial pairing

- ✅ Quantity: 1 set (3 pieces)

- ✅ Manufacturing: Swiss-made quality

- ✅ Design: Clean aesthetic without branding

6. Bezel Click Spring Replacement for Rolex Submariner 🌊

Critical for maintaining proper bezel function on rolex watch dial assemblies, this aftermarket spring ensures precise clicking action and secure bezel positioning on Submariner models.

Component Details:

- ✅ Model: WCP-AMZ-CS16800

- ✅ Compatibility: Rolex Submariner

- ✅ Function: Bezel click mechanism

- ✅ Material: Precision spring steel

- ✅ Installation: Professional recommended

7. Screw Pins Links Watch Band Bracelet Replacement 🔩

Essential hardware for maintaining rolex watch dial frame integrity, these precision screws ensure secure bracelet attachment and proper case alignment for optimal dial presentation.

Hardware Specifications:

- ✅ Application: Watch band repair

- ✅ Compatibility: Rolex models

- ✅ Material: Precision steel

- ✅ Function: Movement and strap security

- ✅ Professional grade: Watchmaker quality

💬 Just one click – help others make better buying decisions too!😊

✨ Transform Your Timepiece Today! 🚀

Ready to elevate your Rolex experience? These carefully selected rolex watch dial components and tools represent the pinnacle of aftermarket quality and precision. Click on any highlighted product to explore current pricing and availability – your perfect customization awaits! ⚱️

Understanding Rolex Watch Dial Fundamentals

The rolex watch dial serves as far more than a mere timekeeping interface; it represents the convergence of artistic expression, technical innovation, and mechanical precision that defines luxury horology. Every rolex dial variation tells a unique story through its material composition, manufacturing process, and design philosophy that has evolved over decades of Swiss craftsmanship.

Modern rolex watch dial technology incorporates advanced materials science, precision manufacturing techniques, and quality control standards that exceed industry benchmarks. From the foundational brass substrate to the final protective coating, each layer contributes to the dial’s longevity, legibility, and aesthetic appeal that collectors worldwide recognize as unmistakably Rolex.

Material Science Behind Rolex Watch Dial Construction

Contemporary rolex dial manufacturing employs sophisticated metallurgy and surface treatment processes that ensure decades of reliable performance under diverse environmental conditions. The primary substrate typically consists of brass alloy specifically formulated for dimensional stability, corrosion resistance, and thermal expansion characteristics that complement the movement’s precision tolerances.

Surface treatments for rolex watch dial variants include electroplating, physical vapor deposition (PVD), and specialized lacquer applications that provide both aesthetic appeal and functional durability. These processes create the distinctive finishes that characterize different Rolex collections while maintaining the optical clarity and contrast necessary for optimal legibility under varying lighting conditions.

Advanced manufacturing techniques such as laser etching, diamond cutting, and micro-machining enable the creation of intricate dial features including minute tracks, logo placements, and text applications that maintain crisp definition throughout the watch’s operational lifespan. These precision processes distinguish genuine rolex dial components from inferior reproductions that lack the dimensional accuracy and surface quality of authentic Swiss manufacturing.

Industry-Specific Applications and Professional Use Cases

Professional applications for rolex watch dial customization extend across multiple industries where precision timekeeping and distinctive appearance serve both functional and symbolic purposes. Aviation professionals, maritime specialists, medical practitioners, and financial executives frequently select specific rolex dial variations that complement their professional requirements while maintaining the prestige associated with luxury Swiss timepieces.

Aviation and Aerospace Applications

Pilots and aviation professionals gravitate toward rolex watch dial configurations featuring high-contrast markings, luminous elements, and GMT functionality that supports navigation and flight planning requirements. The distinctive 24-hour bezels and dual-time zone capabilities found on GMT-Master models provide essential functionality for international flight operations while maintaining the reliability standards demanded by professional aviation.

Commercial airline pilots often prefer rolex dial options with clean, uncluttered layouts that facilitate quick time reference during critical flight phases. The distinctive Mercedes-style hands and prominent hour markers characteristic of aviation-oriented Rolex models ensure optimal readability under cockpit lighting conditions while supporting the split-second timing decisions that define professional flight operations.

Military aviation applications require rolex watch dial specifications that withstand extreme temperature variations, vibration, and electromagnetic interference common in tactical flight environments. The robust construction and precision manufacturing of genuine Rolex dials provides the reliability and accuracy essential for mission-critical timing requirements where equipment failure could compromise operational success.

Maritime and Nautical Professional Applications

Marine professionals including yacht captains, naval officers, and commercial vessel operators rely on rolex watch dial features specifically designed for maritime environments. The Submariner and Sea-Dweller models incorporate dial technologies optimized for underwater visibility, pressure resistance, and corrosion protection that surpass standard diving watch specifications.

Professional diving applications require rolex dial configurations that maintain legibility at extreme depths where ambient light penetration becomes minimal. The Chromalight luminescent technology incorporated in modern Rolex dials provides extended illumination duration and enhanced visibility compared to traditional luminous materials, supporting safe diving operations in challenging underwater environments.

Competitive sailing and yacht racing professionals utilize rolex watch dial features including regatta timers, countdown functions, and high-precision chronograph capabilities that support tactical race management and navigation timing. The instantaneous chronograph reset and precise timing accuracy of Daytona models provide the competitive advantages essential for professional sailing success at the highest levels of international competition.

Medical and Healthcare Professional Applications

Healthcare professionals including surgeons, emergency medicine physicians, and specialized practitioners select rolex watch dial configurations that support precise timing requirements while maintaining the professional appearance appropriate for patient care environments. The antimicrobial properties of certain dial finishes and the ease of cleaning associated with smooth dial surfaces make specific Rolex models particularly suitable for medical applications.

Surgical timing applications require rolex dial features that enable precise procedure timing, medication scheduling, and anesthesia monitoring without compromising sterile field integrity. The distinctive click bezel mechanisms and prominent minute markers found on select Rolex models provide the timing precision essential for critical medical procedures where accuracy can impact patient outcomes.

Emergency medical applications benefit from rolex watch dial configurations featuring high-visibility markings, shock resistance, and reliable mechanical operation that continues functioning under extreme stress conditions common in emergency response situations. The robust construction and precision engineering of genuine Rolex movements ensure continued operation when electronic timing devices might fail due to environmental conditions or electromagnetic interference.

Advanced Technical Analysis and Engineering Principles

The engineering principles underlying rolex watch dial design reflect decades of research and development focused on optimizing legibility, durability, and aesthetic appeal within the constraints of miniaturized mechanical systems. Advanced computer-aided design (CAD) techniques, finite element analysis (FEA), and precision manufacturing processes enable the creation of dial components that achieve dimensional tolerances measured in micrometers while maintaining the visual appeal that defines luxury timepieces.

Precision Manufacturing and Quality Control

Modern rolex watch dial production incorporates statistical process control (SPC) methodologies, automated inspection systems, and multi-stage quality verification protocols that ensure every component meets exacting specifications before assembly integration. These quality control measures include dimensional verification, surface finish analysis, color matching protocols, and adhesion testing that validate long-term durability under operational conditions.

Laser measurement systems verify rolex dial component dimensions to tolerances of ±0.005mm, ensuring proper fit with movement components and maintaining the precise clearances necessary for reliable timekeeping accuracy. Surface roughness measurements confirm finish quality standards that affect both aesthetic appearance and long-term durability under diverse environmental conditions.

Color matching protocols for rolex watch dial production utilize spectrophotometric analysis to ensure consistency across production batches and compatibility with existing watch collections. These precision color control measures maintain the brand recognition and visual consistency that collectors expect from authentic Rolex timepieces while supporting customization options that complement individual preferences.

Advanced Materials and Surface Technologies

Contemporary rolex dial manufacturing incorporates advanced materials including ceramic composites, precious metal alloys, and specialized coatings that provide enhanced durability and distinctive aesthetic properties. These materials undergo extensive testing protocols including accelerated aging, environmental exposure, and wear resistance evaluation to validate long-term performance under operational conditions.

Ceramic dial applications offer superior scratch resistance, fade resistance, and dimensional stability compared to traditional materials while enabling color options and surface textures not achievable with conventional manufacturing processes. The high-temperature sintering processes used in ceramic dial production create molecular bonds that provide exceptional durability and maintain appearance integrity throughout decades of regular use.

Precious metal dial applications including gold, platinum, and specialized alloys provide distinctive appearance characteristics while offering superior corrosion resistance and dimensional stability. The precision machining and surface finishing techniques used in precious metal dial production create the distinctive appearance and tactile qualities that define luxury timepiece applications.

Comprehensive Setup and Installation Procedures

Professional rolex watch dial installation requires specialized tools, controlled environmental conditions, and extensive technical knowledge to ensure proper component integration and long-term reliability. The precision tolerances and delicate nature of dial components demand careful handling procedures and specific installation techniques that preserve both functional and aesthetic integrity.

Pre-Installation Preparation and Assessment

Proper rolex dial installation begins with comprehensive assessment of existing watch components, documentation of current configuration, and verification of replacement part compatibility. This assessment includes movement identification, case condition evaluation, and existing dial condition analysis that informs the installation strategy and identifies potential complications.

Component compatibility verification involves detailed comparison of specifications including dial size, mounting post dimensions, hand clearances, and movement caliber requirements. Proper verification prevents installation problems that could damage movement components or compromise timekeeping accuracy while ensuring optimal aesthetic integration with existing watch elements.

Environmental preparation for rolex watch dial installation includes establishing dust-free work areas, controlling temperature and humidity conditions, and organizing specialized tools and components in proper sequence. These environmental controls prevent contamination that could affect movement operation or dial appearance while supporting the precision work required for successful installation.

Detailed Installation Methodology

Professional rolex dial installation follows specific sequences that minimize risk to movement components while ensuring proper alignment and secure mounting. The installation process typically requires movement removal from the case, dial and hand removal, replacement component preparation, and systematic reassembly with appropriate quality control checkpoints.

Movement handling during rolex watch dial installation requires specialized tools including movement holders, hand pullers, dial removal tools, and precision alignment fixtures that prevent damage to delicate components. Proper tool selection and handling techniques ensure successful installation while maintaining the precision tolerances necessary for accurate timekeeping performance.

Quality control verification throughout the installation process includes dimensional checks, clearance verification, functional testing, and aesthetic assessment that confirms proper installation before final assembly. These verification steps prevent problems that could require disassembly and reinstallation while ensuring optimal performance and appearance of the completed timepiece.

Post-Installation Testing and Calibration

Comprehensive testing following rolex watch dial installation includes timekeeping accuracy verification, crown function testing, bezel operation assessment, and water resistance validation where applicable. These tests confirm that installation procedures have not compromised watch functionality while validating the performance standards expected from luxury timepieces.

Timekeeping accuracy testing involves precision timing measurements over extended periods using specialized timing equipment that detects variations in rate stability and amplitude consistency. These measurements verify that dial installation has not affected movement performance while identifying any adjustments needed to maintain manufacturer specifications.

Functional testing protocols include crown operation verification, pushbutton function assessment where applicable, and bezel rotation testing that confirms proper component interaction. These tests ensure that all watch functions operate smoothly and reliably following dial installation while maintaining the user experience expected from luxury timepieces.

Maintenance and Longevity Optimization

Long-term preservation of rolex watch dial appearance and functionality requires systematic maintenance protocols, environmental protection measures, and periodic professional service that addresses both visible and internal components. Proper maintenance practices significantly extend dial lifespan while preserving the aesthetic qualities and functional performance that define luxury timepiece ownership.

Daily Care and Environmental Protection

Daily maintenance of rolex watch dial components involves gentle cleaning procedures, protection from impact damage, and awareness of environmental factors that could affect appearance or functionality. Regular cleaning with appropriate materials and techniques prevents accumulation of contaminants that could cause permanent staining or surface damage while maintaining the pristine appearance expected from luxury timepieces.

Environmental protection measures include avoiding exposure to strong magnetic fields, extreme temperatures, chemicals, and excessive moisture that could damage dial components or affect movement operation. Understanding these environmental factors and implementing appropriate protection strategies significantly extends the operational lifespan of both dial and movement components.

Impact protection during daily wear involves awareness of activities that could cause shock damage to delicate dial components including sports participation, manual labor, and transportation in environments where vibration or impact could occur. Proper awareness and protection strategies prevent damage that could require expensive repair or component replacement.

Weekly and Monthly Maintenance Protocols

Weekly maintenance protocols for rolex watch dial preservation include detailed visual inspection, gentle cleaning procedures, and functional testing that identifies potential problems before they require professional intervention. These routine maintenance practices maintain optimal appearance and functionality while supporting early detection of issues that could affect long-term reliability.

Monthly maintenance procedures include more comprehensive cleaning protocols, crown lubrication assessment, and timing accuracy monitoring that provides insight into overall watch condition and performance trends. These monthly assessments support preventive maintenance strategies that avoid major problems while maintaining the precision performance expected from luxury timepieces.

Documentation of maintenance activities including cleaning dates, observed condition changes, and timing measurements provides valuable historical information that supports professional service decisions and warranty considerations. Proper maintenance documentation demonstrates responsible ownership while facilitating professional service when required.

Professional Service and Restoration Protocols

Professional service intervals for rolex watch dial maintenance typically occur every 5-10 years depending on usage patterns, environmental exposure, and observed condition changes. Professional service includes comprehensive movement cleaning, lubrication, adjustment, and replacement of worn components that affect timekeeping accuracy or reliability.

Dial restoration services available through authorized Rolex service centers and qualified independent watchmakers can address issues including surface refinishing, marker replacement, hand restoration, and protective coating renewal. These restoration services can significantly extend dial lifespan while maintaining authentic appearance characteristics that preserve collection value.

Component replacement protocols during professional service include evaluation of dial condition, assessment of replacement part availability, and cost-benefit analysis that considers restoration versus replacement options. Professional guidance ensures optimal decisions that balance performance, appearance, and economic considerations while maintaining authentic Rolex characteristics.

Comparative Analysis: Factory vs. Aftermarket Options

The choice between factory original and aftermarket rolex watch dial components involves complex considerations including authenticity, cost, availability, customization options, and long-term value implications. Understanding the advantages and limitations of each option enables informed decisions that align with individual priorities and collection objectives.

Factory Original Dial Characteristics

Factory original rolex dial components offer guaranteed authenticity, precise manufacturing tolerances, and material quality that meets the exacting standards established by Rolex throughout decades of luxury timepiece production. These components maintain the original design intent and aesthetic characteristics that define specific model variations while ensuring compatibility with existing movement and case components.

Quality control standards for factory rolex dial production exceed industry benchmarks through implementation of advanced manufacturing processes, precision measurement systems, and comprehensive testing protocols that validate performance under diverse operational conditions. These quality standards result in components that provide decades of reliable service while maintaining the appearance characteristics that define luxury timepiece ownership.

Availability and pricing considerations for factory original rolex dial components reflect the exclusivity and manufacturing complexity associated with Swiss luxury timepiece production. Limited availability and premium pricing protect brand exclusivity while ensuring that genuine components maintain their distinctive characteristics and performance standards.

Aftermarket Dial Options and Considerations

Aftermarket rolex watch dial components provide customization opportunities, cost advantages, and availability benefits that may not be achievable through factory channels. Quality aftermarket suppliers offer components manufactured to specifications that approach or equal factory standards while providing options for personalization and unique aesthetic expressions.

Manufacturing quality among aftermarket rolex dial suppliers varies significantly, with premium suppliers offering components that meet Swiss manufacturing standards while budget options may compromise quality, fit, or appearance characteristics. Careful supplier selection and component evaluation ensure optimal results while avoiding problems associated with inferior manufacturing.

Customization capabilities available through aftermarket rolex dial suppliers include unique materials, color options, marker styles, and surface treatments that enable personalization beyond factory offerings. These customization options support individual expression while maintaining the fundamental characteristics that define Rolex aesthetic appeal.

Case Studies and Implementation Success Stories

Real-world applications of rolex watch dial customization and restoration demonstrate the practical benefits and challenges associated with these specialized services. Professional case studies provide insight into decision-making processes, implementation strategies, and outcomes that inform similar projects while illustrating best practices for successful dial modifications.

Professional Restoration Project: Vintage Submariner

A comprehensive restoration project involving a 1960s Submariner required careful evaluation of original dial condition, research into period-correct replacement options, and implementation of restoration techniques that preserved historical authenticity while ensuring reliable functionality. The project demonstrated the importance of detailed research and specialized expertise in achieving optimal results.

Initial assessment revealed significant dial deterioration including lume degradation, surface corrosion, and marker damage that compromised both appearance and legibility. Professional evaluation determined that restoration rather than replacement would preserve historical value while achieving functional and aesthetic objectives.

Restoration implementation involved specialized cleaning techniques, surface refinishing, lume renewal, and protective coating application using methods appropriate for vintage components. The restoration process required extensive research into period-correct materials and techniques that maintained historical accuracy while ensuring long-term durability.

Project outcomes included restored dial functionality, improved legibility, and preserved historical characteristics that maintained collection value while ensuring reliable daily operation. The successful restoration demonstrated the value of professional expertise and appropriate restoration techniques in preserving vintage timepiece integrity.

Custom Dial Project: Modern Daytona

A custom dial project for a modern Daytona involved collaboration between the owner, dial manufacturer, and installation specialist to create a unique aesthetic expression while maintaining functional reliability and aesthetic coherence. The project illustrated the potential for personalization within the constraints of mechanical and aesthetic requirements.

Design development included material selection, color specification, marker configuration, and surface treatment selection that achieved the desired aesthetic while ensuring compatibility with existing movement and case components. Collaborative design processes ensured optimal results while avoiding potential compatibility issues.

Manufacturing implementation utilized advanced production techniques including laser cutting, precision machining, and specialized surface treatments that created the desired appearance while maintaining the dimensional accuracy necessary for proper installation and operation.

Installation and testing protocols verified proper fit, functional operation, and aesthetic integration while ensuring that customization did not compromise timekeeping accuracy or reliability. Comprehensive testing validated the successful integration of custom components with existing watch systems.

Collection Enhancement Project: Multiple Model Upgrades

A comprehensive collection enhancement project involved dial upgrades across multiple Rolex models to create aesthetic coherence while maintaining individual model characteristics. The project demonstrated strategies for systematic collection development and the coordination required for multiple simultaneous modifications.

Planning and coordination activities included condition assessment of existing watches, design development for consistent aesthetic themes, supplier selection and quality verification, and scheduling coordination to minimize collection downtime during modification processes.

Implementation challenges included maintaining quality consistency across multiple suppliers, coordinating timing for simultaneous work, and ensuring aesthetic coherence while respecting individual model characteristics. Professional project management techniques proved essential for successful completion.

Results achieved included improved collection coherence, enhanced individual watch appearance, and maintained functionality across all modified timepieces. The project demonstrated the potential for systematic collection enhancement while illustrating the complexity and coordination required for successful implementation.

Future Trends and Market Evolution

The rolex watch dial market continues evolving through technological advancement, material innovation, and changing consumer preferences that influence both factory production and aftermarket offerings. Understanding emerging trends provides insight into future opportunities and challenges while informing strategic decisions for collectors and enthusiasts.

Technological Innovation and Advanced Materials

Emerging technologies in rolex watch dial production include advanced ceramic composites, nano-surface treatments, and precision manufacturing techniques that enable new aesthetic possibilities while improving durability and performance characteristics. These technological advances expand customization options while maintaining the quality standards associated with luxury timepiece components.

Nano-coating technologies provide enhanced scratch resistance, improved legibility, and extended durability compared to traditional surface treatments while enabling new aesthetic effects and color options. These advanced coatings represent significant improvements in dial protection and appearance while supporting customization opportunities not previously achievable.

Advanced manufacturing techniques including 3D printing, laser sintering, and micro-machining enable component geometries and surface textures that exceed the capabilities of traditional manufacturing processes. These techniques support increased customization possibilities while maintaining the precision and quality standards expected from luxury timepiece components.

Market Trends and Consumer Preferences

Consumer preferences in rolex watch dial customization reflect broader trends toward personalization, sustainability, and value optimization that influence purchasing decisions and modification choices. Understanding these trends provides insight into market direction and opportunities for both suppliers and consumers.

Personalization trends emphasize unique aesthetic expressions that reflect individual taste and lifestyle while maintaining the fundamental characteristics that define Rolex brand identity. These trends support growth in custom dial services while creating opportunities for specialized suppliers and service providers.

Sustainability considerations increasingly influence component selection and manufacturing processes as consumers become more conscious of environmental impact and resource utilization. These considerations drive innovation in materials and processes while creating opportunities for sustainable manufacturing approaches.

Value optimization strategies focus on achieving maximum aesthetic and functional improvement while managing cost and maintaining collection value. These strategies require careful analysis of modification impact on both immediate satisfaction and long-term value preservation.

Industry Predictions and Development Directions

Industry evolution in rolex watch dial manufacturing and customization will likely emphasize increased customization options, improved manufacturing efficiency, and enhanced integration between factory and aftermarket offerings. These developments will create new opportunities for personalization while maintaining the quality and authenticity standards that define luxury timepiece ownership.

Artificial intelligence and machine learning applications in dial design and manufacturing will enable more precise customization options while optimizing production efficiency and quality control. These technologies will support increased personalization possibilities while maintaining the consistency and reliability expected from luxury timepiece components.

Integration between authorized service channels and aftermarket suppliers may increase as consumer demand for customization options grows while brand protection requirements evolve. This integration could provide expanded customization options while maintaining warranty coverage and authenticity guarantees.

Detailed Comparison Tables and Analysis

Rolex Watch Dial Material Comparison

| Material Type | Durability Rating | Aesthetic Appeal | Cost Range | Maintenance Requirements | Availability |

|---|---|---|---|---|---|

| Factory Metal | Excellent (9/10) | Classic (8/10) | $400-$1,500 | Low | Limited |

| Mother of Pearl | Good (7/10) | Elegant (9/10) | $300-$1,200 | Medium | Moderate |

| Diamond Set | Excellent (9/10) | Luxury (10/10) | $1,000-$5,000+ | High | Limited |

| Ceramic | Outstanding (10/10) | Modern (8/10) | $500-$2,000 | Very Low | Growing |

| Aftermarket Custom | Variable (6-9/10) | Unique (7-10/10) | $150-$800 | Medium | High |

Compatibility Matrix: Rolex Models and Dial Options

| Rolex Model | Dial Size | Movement Type | Compatible Aftermarket | Installation Difficulty | Average Cost |

|---|---|---|---|---|---|

| Submariner | 40mm/41mm | 3135/3235 | High | Professional | $300-$800 |

| Datejust | 36mm/41mm | 3135/3235 | Very High | Professional | $250-$700 |

| Daytona | 40mm | 4130 | Moderate | Expert | $400-$1,200 |

| GMT-Master II | 40mm | 3186/3285 | High | Professional | $350-$900 |

| Day-Date | 36mm/40mm | 3155/3255 | Moderate | Expert | $500-$1,500 |

| Oyster Perpetual | 36mm/41mm | 3130/3230 | High | Professional | $200-$600 |

| Sea-Dweller | 43mm | 3235 | Limited | Expert | $400-$1,000 |

Cost-Benefit Analysis: Factory vs. Aftermarket

| Consideration | Factory Original | Premium Aftermarket | Budget Aftermarket |

|---|---|---|---|

| Initial Cost | High ($500-$2,000+) | Medium ($200-$800) | Low ($100-$300) |

| Authenticity | Guaranteed | Variable | Not guaranteed |

| Warranty Impact | Maintained | Voided | Voided |

| Resale Value | Preserved/Enhanced | Reduced | Significantly reduced |

| Customization | Limited | High | High |

| Quality Consistency | Guaranteed | Variable | Variable |

| Availability | Limited | Good | Excellent |

Installation Requirements and Professional Services

| Service Level | Typical Cost | Time Required | Warranty | Quality Assurance | Recommended For |

|---|---|---|---|---|---|

| Authorized Service | $300-$800+ | 2-6 weeks | Full | Guaranteed | Valuable pieces |

| Independent Professional | $150-$400 | 1-2 weeks | Limited | High | Regular maintenance |

| Experienced Hobbyist | $50-$150 | 1-3 days | None | Variable | Learning projects |

| DIY Installation | $0-$50 | 2-8 hours | None | User dependent | Simple replacements |

✨ Upgrade Your Collection Today! 💎

Transform your Rolex timepiece with these expertly curated rolex watch dial options and professional-grade tools. Whether you’re seeking authentic restoration parts or exploring custom personalization possibilities, these top-rated products deliver the quality and precision your luxury timepiece deserves. Click any product link to check current availability and pricing! 🚀

Professional Installation and Safety Considerations

Professional installation of rolex watch dial components requires specialized expertise, precision tools, and controlled environmental conditions to ensure successful outcomes without damaging valuable timepiece components. The delicate nature of mechanical watch movements and the precision tolerances involved in dial installation make professional service strongly recommended for valuable timepieces.

Safety considerations during rolex dial installation include proper electrostatic discharge (ESD) protection, contamination prevention, and appropriate handling techniques that prevent damage to sensitive components. Professional watchmakers utilize specialized equipment including anti-static work surfaces, filtered air systems, and precision lighting that creates optimal conditions for delicate assembly work.

Risk assessment for DIY dial installation should consider the value of the timepiece, availability of replacement parts, complexity of the specific model, and consequences of potential damage. While simpler procedures may be attempted by experienced hobbyists, valuable or complex timepieces should always receive professional service to prevent costly damage.

Troubleshooting Common Issues and Solutions

Common problems encountered during rolex watch dial work include misalignment issues, clearance problems, adhesion failures, and aesthetic inconsistencies that can affect both appearance and functionality. Understanding these potential issues and their solutions helps prevent problems and ensures successful outcomes when they occur.

Alignment and Fit Issues

Dial misalignment problems typically result from improper positioning during installation, worn mounting posts, or dimensional variations between original and replacement components. Professional correction requires precise measurement, proper alignment tools, and sometimes modification of mounting hardware to achieve proper positioning.

Clearance problems between dial and hands often indicate dimensional variations or installation errors that prevent proper hand movement. Resolution requires careful measurement of clearances, assessment of component compatibility, and sometimes hand modification or replacement to achieve proper operation.

Adhesion and Mounting Problems

Dial mounting failures can result from improper adhesive selection, surface preparation issues, or environmental factors during installation. Successful resolution requires proper surface cleaning, appropriate adhesive selection, and controlled environmental conditions during the bonding process.

Long-term adhesion problems may indicate incompatible materials, temperature cycling effects, or moisture infiltration that compromises the bond between dial and movement. Professional assessment and repair using appropriate materials and techniques ensures reliable long-term mounting.

Aesthetic and Functional Integration

Color matching problems between new and existing components require careful assessment of lighting conditions, surface finishes, and aging effects that influence perceived color harmony. Professional color matching techniques and specialized lighting ensure optimal aesthetic integration.

Functional integration issues including crown operation, pushbutton function, or bezel rotation problems may indicate interference between new and existing components. Systematic diagnosis and appropriate modification ensure proper function while maintaining aesthetic objectives.

Advanced Customization Techniques and Options

Advanced rolex watch dial customization encompasses techniques including material modification, surface treatment, marker addition or removal, and integration of specialized features that create unique aesthetic expressions while maintaining functional reliability. These advanced techniques require specialized equipment and expertise that typically necessitate professional implementation.

Surface Treatment and Finishing

Specialized surface treatments including texturing, plating, and coating application can dramatically alter dial appearance while providing enhanced durability and unique aesthetic characteristics. Professional implementation ensures optimal results while maintaining the dimensional accuracy necessary for proper installation and operation.

Refinishing techniques for existing dials include surface restoration, color modification, and protective coating application that can revitalize appearance while maintaining original character. These techniques require specialized equipment and expertise to achieve professional results without compromising structural integrity.

Marker and Feature Modification

Custom marker installation including diamond setting, alternative materials, or unique designs requires precision machining, specialized adhesives, and careful integration with existing dial features. Professional implementation ensures proper positioning, secure mounting, and aesthetic harmony with overall design objectives.

Feature addition or removal including date windows, subdials, or logo modifications requires extensive mechanical knowledge and specialized tools to maintain movement compatibility while achieving desired aesthetic outcomes. These modifications should only be attempted by experienced professionals with appropriate equipment and expertise.

Quality Assurance and Testing Protocols

Comprehensive quality assurance for rolex watch dial work includes dimensional verification, functional testing, aesthetic assessment, and long-term durability validation that ensures optimal results and reliable performance. Professional quality control protocols prevent problems and validate successful completion before returning timepieces to their owners.

Performance Validation Testing

Timekeeping accuracy testing following dial installation verifies that modifications have not affected movement performance while confirming that installation procedures were completed successfully. Professional timing equipment measures rate stability, amplitude consistency, and beat error that indicate proper movement function.

Functional testing protocols include crown operation, pushbutton assessment, and bezel function verification that confirms proper component interaction following dial installation. These tests ensure that all watch functions operate smoothly and reliably while maintaining the user experience expected from luxury timepieces.

Long-term Durability Assessment

Accelerated aging tests simulate extended operational conditions to validate component durability and identify potential failure modes before they occur in normal use. These tests provide confidence in modification longevity while identifying any adjustments needed to ensure optimal long-term performance.

Environmental testing including temperature cycling, humidity exposure, and vibration assessment validates component performance under diverse operational conditions while ensuring that modifications maintain their appearance and functionality throughout extended use periods.

Conclusion

The world of rolex watch dial customization offers endless possibilities for personal expression while maintaining the technical excellence and aesthetic appeal that define luxury Swiss timepieces. From factory-original restorations that preserve authenticity to custom aftermarket creations that reflect individual style, the options available today surpass anything previously accessible to collectors and enthusiasts.

Understanding the technical requirements, quality considerations, and professional expertise necessary for successful dial work enables informed decisions that balance personal preferences with practical constraints. Whether pursuing authentic restoration, subtle enhancement, or dramatic customization, the key lies in selecting appropriate components, qualified service providers, and implementation strategies that achieve desired outcomes while preserving the fundamental characteristics that make Rolex timepieces coveted worldwide.

The investment in quality rolex watch dial components and professional installation services pays dividends through enhanced appearance, maintained reliability, and personal satisfaction that comes from owning a truly unique timepiece. As manufacturing techniques continue advancing and customization options expand, the future holds even greater opportunities for creating personalized expressions of horological excellence.

Frequently Asked Questions

❓ What is the typical cost range for a professional rolex watch dial replacement?

✅ Professional rolex watch dial replacement costs typically range from $300-$1,500 depending on dial type and complexity. Factory original dials from authorized service centers cost $500-$2,000+, while quality aftermarket options range $200-$800. Installation costs add $150-$400 for professional service...

❓ How long does a rolex dial replacement take at a professional service center?

✅ Professional rolex dial replacement typically requires 1-3 weeks for independent watchmakers and 2-6 weeks for authorized Rolex service centers. Complex modifications or custom dial installations may require additional time for sourcing parts and specialized procedures. Expedited service may be available for additional fees...

❓ Will replacing my rolex watch dial void the manufacturer warranty?

✅ Yes, installing non-factory dial components will void your Rolex manufacturer warranty. Only authorized Rolex service centers using genuine factory parts maintain warranty coverage. However, quality aftermarket dials can be removed and replaced with original components to restore warranty eligibility if needed...

❓ What tools are required for professional rolex watch dial installation?

✅ Professional rolex watch dial installation requires specialized tools including case openers, hand pullers, dial removal tools, movement holders, and precision alignment fixtures. The Rolex 5537 case opener kit costs around $50-$100 and includes six graduated dies for different case sizes. Professional installation also requires clean room conditions and timing equipment...

❓ Can I install a rolex watch dial myself without professional experience?

✅ DIY rolex dial installation is extremely challenging and risks damaging valuable components. While simple band changes are possible, dial installation requires removing the movement, handling delicate parts, and precise reassembly. Mistakes can cost hundreds or thousands in repair fees. Professional service is strongly recommended for valuable timepieces...

Recommended for You

- 7 Best Rolex Leather Watch Band Options for Ultimate Style and Comfort in 2025

- 7 Best Rolex Watch Bracelet Options For Ultimate Style and Durability in 2025

- 7 Best Two Tone Rolex Watch Alternatives For Ultimate Luxury in 2025

Disclaimer: This article contains affiliate links. If you purchase products through these links, we may earn a small commission at no additional cost to you.

✨ Found this helpful? Share it with your friends! 💬🤗